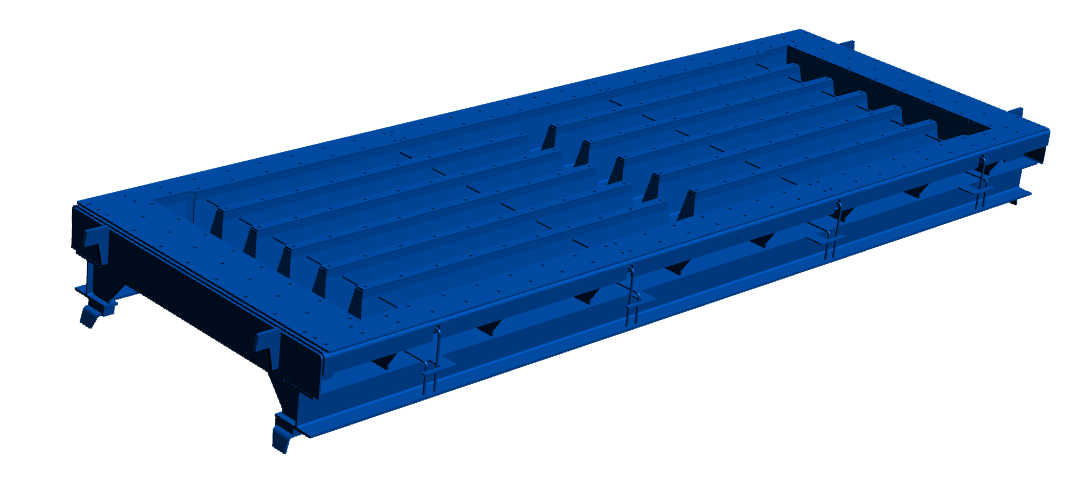

With our own in house design team utilising the latest 3D technology and design software we can design and manufacture any mould to suit your product needs.

-

Dry Cast Mouldage Production Run

- Cement, aggregates & pigments and blended together to create a dry or semi-dry mix, which is then deposited into a mould via a Coote Filling System.

- The mix is poured into the Dry Cast moulds which are manufactured from steel bodies designed to suit your individual product needs.

- The dry mix is tipped out into the mould and vibrated. It is then also screeded to create a flat smooth surface

- The product is removed from the mould to be stacked. Stacking can be either manual or fully automated through a robotic arm or another robotic system.

-

Potential industries for Dry Cast Moulds

- Construction

- Construction

- Railway Projects

- Residential Buildings

- Commercial Buildings

- Agricultural Products

- Marine Projects

Gallery

+44 (0)28 8556 8123

+44 (0)28 8556 8123

office@coote.co.uk

office@coote.co.uk