Used for the production of products up to 1.75m in diameter and up to 1.0m in length

The Multicast consists of a feeding unit with rotary feeding, vibrating table and a press head. The Multicast produces cones inside dia. up to 1.5m with a height of 1.0m, manhole risers inside dia. up to 1.8m with a height of 0.33, 0.5, 0.66 and 1.0m and trapped & untrapped Gullies.

-

Multicast Production Run

- The concrete holding hopper is filled with concrete.

- The operator moves the distribution belt forward over the mould that is clamped onto the vibrating table.

- The operator activates the distribution belt and the concrete begins the rotation of the concrete divider.

- The vibration is activated and the operator continues to fill the mould with concrete.

- Once the mould is filled, the operator retracts the distribution conveyor and moves the press head into position.

- The press head is then lowered into the top of the mould and the rotation begin. This leaves the upper profile on the product.

- When the press head is finished it is moved out of the area and the vibrating table clamps are released.

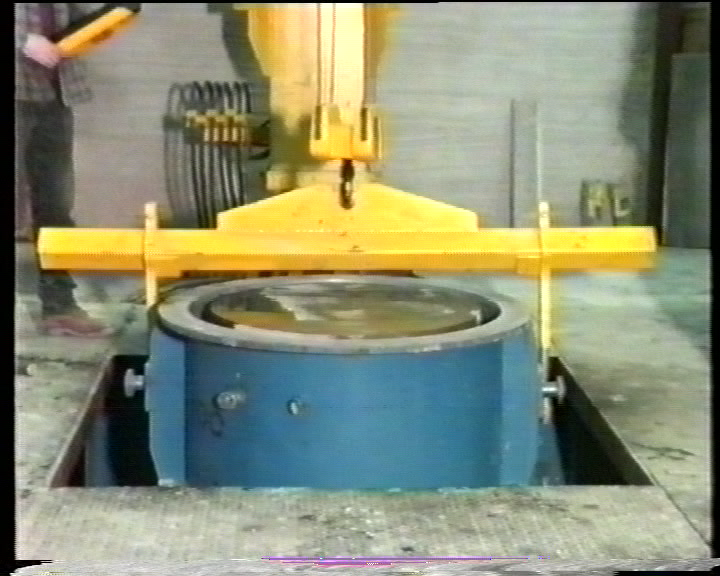

- An overhead gantry is fastened to the mould and it is lifted clear of the vibrating table.

- The mould is set down at a certain position and the bottom ring is released. This allows the product to be removed from the mould straight away.

- The mould is then set on another base ring to clamp it and is then set back down onto the vibrating table for the process to begin again.

-

Multicast Specifications

- Production

- Product Size

- Product surface area

- Hopper Capacity

- Hopper Movement

- Feed Belt Length

- Feed Belt Width

- Vibrating table adjustment

- Circular heads rotation

- Concrete Divider:

- Operations

- Operator Controls

- Control Panel

30 – 40 products per shift (Product Dependant)

Up to 1800mm in diameter and 1000mm in height

1800mm x 1800mm

0.8m³

lifted and lowered 500mm

2500mm

600mm

500mm

Up to 20 degrees

operates in a diameter of 1.8m maximum and 0.8m minimum.

Hydraulics

Manual

Hydraulics controlled from lever bank with electrical push buttons operated specific functions

Gallery

+44 (0)28 8556 8123

+44 (0)28 8556 8123

office@coote.co.uk

office@coote.co.uk